Eco-Friendly

Our company had established a long-term cooperation with several domestic processional academy and composite raw materials manufacturers. Advanced automatic production line, excellent technology and experienced engineers assure we can provide you the products comply with the international standards and different requirements. Professional working team, high efficiency reaction and rich experience assure that you will be satisfied with the products and service from us.

We have won over 300 customers from different countries. And more and more customers are joining us. Ecocore New Material is your reliable partner.

What Quality Epoxy Resin Sheet Means For You

Pre-sales Advantages

Our experienced R&D starts with a deep understanding of our customers' business goals, challenges and needs.After analyzing theseneeds, they could providesetsof efficient solutions for customers accordingly to improve the work efficiencyandreduce the cost.

Packaging

By meticulously analyzing appearance data – dimensions, shapes, weights, textures, and special chemical or physical properties – and skillfully combining packaging materials(wooden boxes, cartons, and wooden pallets), we ensure the safe and efficient flow of industrial materials across the supply chain, facilitating smooth industrial production.

Logistics

For transportation, we cover all bases – sea, land, and air. Our intelligent transport system optimizes routes considering real-time traffic, weather, and other elements, smartly devising the most efficient foreign trade logistics routes and methods, and dynamically adjusting vehicle or vessel paths to enhance transport efficiency.

After-sales

Our after-sales team is ready to offer instant technical support, fixing any product usage problems. This underlines our dedication to your satisfaction.We actively seek feedback like potential defects and new demands, quickly passing it to R&D for ongoing product improvement.

Certified by lso9001-2015

As an lSO9001 certified enteriprise,ECOCORE New Material is following strict rules to assure constantlyhigh quality product.

Quality goals:

On time delivery rate≥95%

Passing rate for finished product ≥95%

Customer satisfaction rate≥95%

Nlumber of customer complain≤0.1%

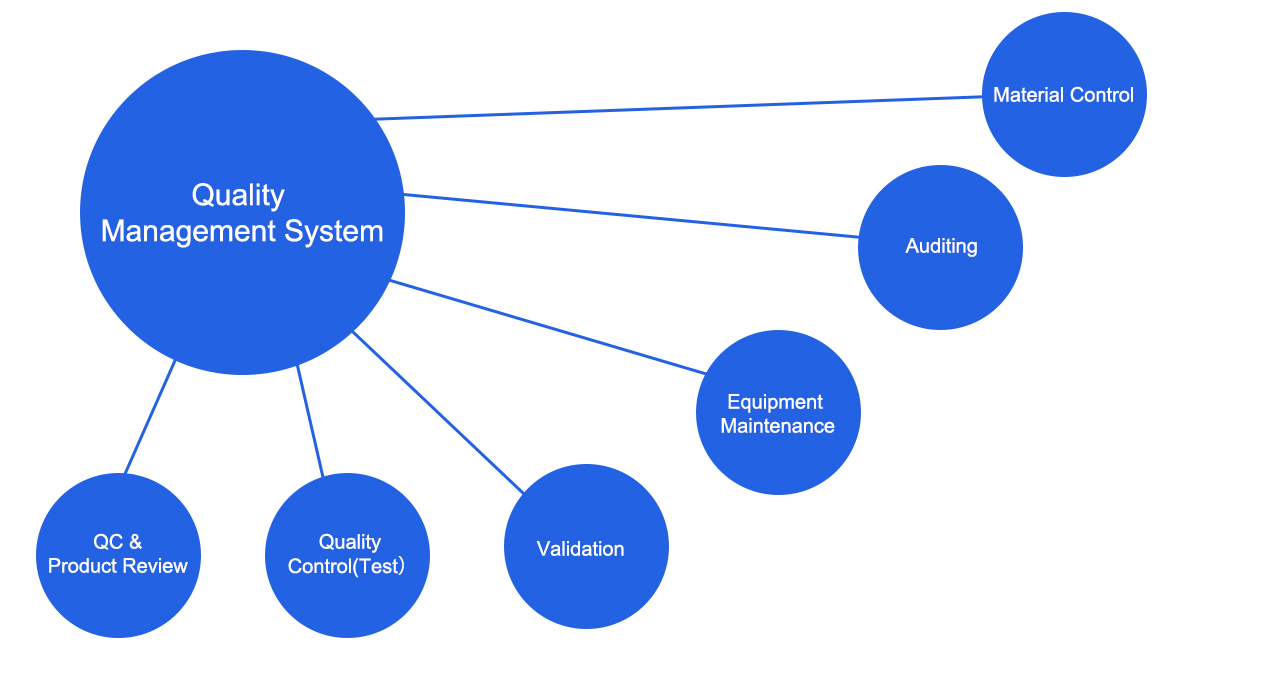

QC Procedure

● According to the customer's use and requirements, recommend more suitable products, which are satisfactory in quality and more advantageous in price;

● According to the comprehensive needs of the customer's product drawings and requirements, as well as the required quantity, we will recommend more suitable production processes: machining, hand lay-up, molding, RTM, autoclave;

● After analyzing the drawings and applications of the product, we will improve and enhance some weak points of the product without affecting the assembly and use of the product.

lQC(Incoming Quality Control)

Every material & component went through strict incoming quality tests before production.

lPQC(In-process Quality Control)

Our inspectors will conduct professional testing in each production process to detectproducts and handle the quality issues in time.

We Put Our Reliability To The Test

Build your reputation for reliability by using lED components that have undergone the mostrigorous global testing and assurance program. So you have the peace of mind of knowingyour customers will have the most satisfying experience whenever they buy your products.

QC Facilities

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction. As a result of our products and outstanding customer service, we have gained a global sales network reaching India, Vietnam, Thailand, Indonesia, Philippines, Malaysia, Turkey, Pakistan, Dubai, and some other countries from European, like Britain, France and German. And America, Australia, etc.

Performance Tests

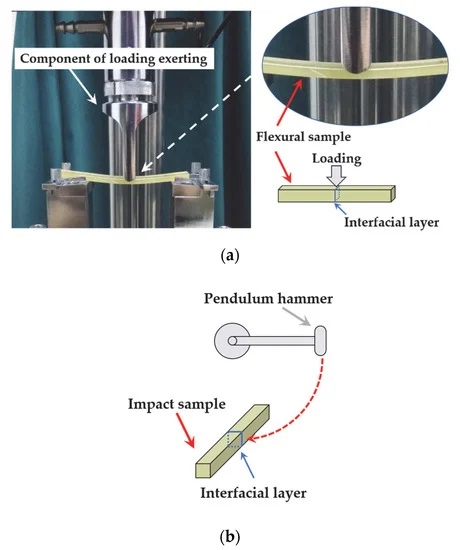

Digital universal testing machine

Name: Digital universal testing machine.Test Items: Tensile strength, compression strength, flexural strength , shear strength and etc.Features: The maximum force is 200kN.

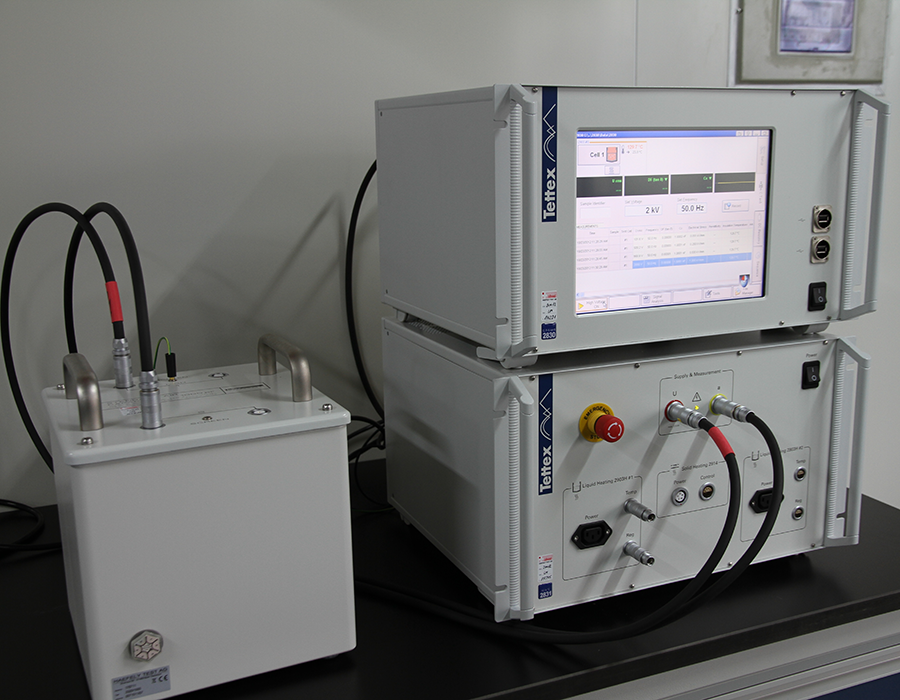

Electrical bridge

Name:Electrical bridge.Test Items:Relative permittivity and dielectric dissipation factor.Features:Adopt contact process and noncontact method to perform normal and hot tests.

Reliability Tests

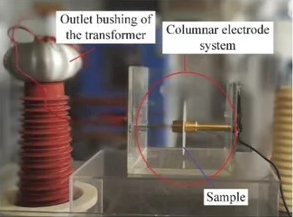

High-voltage breakdown tester

Name:High-voltage breakdown tester.Test Items:Breakdown voltage,dielectric strength and voltage resistance.Features:The maximum voltage can reach 200kV.

Test of impact strength

(b) the test of impact strength. The load was applied on the interfacial region during the test of flexural strength and impact strength.

Laboratory Tests

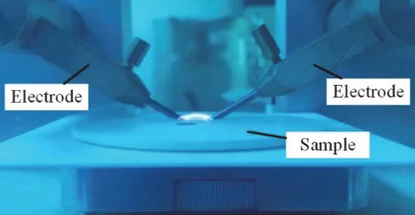

Breakdown system

Arc ablation resistance test.

Dielectric Strength tester 5000V

Certificates

ECOCORE New Material undergo QC policy-strictly from lQC,IPQC,FQC to OQC, from product design process to aftersales process.