Recent Posts

-

What's the difference between FR-4 and 3240 epoxy fiberglass sheet?

Fr-4 and 3240 are the two most common epoxy plates currently on the market.Everyone says the fr-4 ep···

24/09/2024

-

How to verify the quality of epoxy board?

Epoxy board is a laminated board, mainly made of epoxy resin adhesive and paper, cotton and other su···

21/06/2024

-

What are the processing methods of epoxy board?

Epoxy board processing products are mainly used in: high and low voltage transformer accessories, av···

30/11/2022

-

Application of epoxy resin insulating parts in power equipment

The application range of epoxy resin insulating parts can generally be used at -60~100℃. The use of ···

20/02/2018

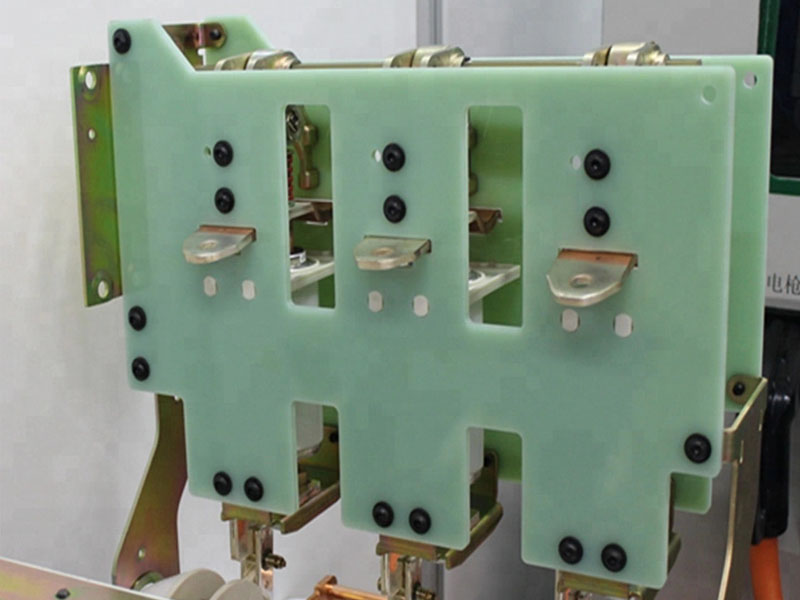

Application of epoxy resin insulating parts in power equipment

The application range of epoxy resin insulating parts can generally be used at -60~100℃. The use of new resins, special curing agents and fillers can be used to formulate ultra-low temperature resistant adhesives (-196℃), high temperature resistant adhesives (350℃), conductive, and magnetic, Heat conduction, spot welding, strain, photosensitive, flame retardant, underwater glue and other special adhesives. Low toxicity, no physiological side effects, harmless to the human body, and can be formulated into environmentally friendly adhesives with low odor and non-toxicity. The toughness is not good, the brittleness is relatively large, and the toughening modification is usually carried out.

Due to its many unique advantages such as high insulation performance, high structural strength and good sealing performance, epoxy resin has been widely used in insulation and packaging of high and low voltage electrical appliances, motors and electronic components, and has developed rapidly. Mainly used for: pouring of electrical and motor insulation packaging. Manufacturing of integrally sealed insulating packages for high and low voltage electrical appliances such as electromagnets, contactor coils, mutual inductors, and dry-type transformers.

It has developed rapidly in the electrical industry. It has developed from normal pressure casting and vacuum casting to automatic pressure gel forming. It is widely used for potting insulation of devices equipped with electronic components and circuits. It has become an indispensable and important insulating material in the electronics industry. Electronic grade epoxy molding compound is used for plastic packaging of semiconductor components. Come to develop extremely fast.

Due to its superior performance, it has a tendency to replace traditional metal, ceramic and glass packaging. Epoxy laminated plastics are widely used in the fields of electronics and electrical appliances. Among them, the development of epoxy copper clad laminate is particularly rapid, and it has become one of the basic materials of the electronics industry. In addition, epoxy insulating coatings, insulating adhesives and electrical adhesives also have a large number of applications.