Recent Posts

Epoxy gasketis a kind of high temperature resistant anti-corrosion sealing gasket, which can directl···

22/01/2025

Epoxy boardis a commonly used material now, and the raw materials for production include epoxy resin···

01/12/2024

Epoxy boardis a commonly used electronic and electrical material, which has the characteristics of h···

20/06/2024

G10 Materialis a composite material composed of glass fiber cloth and epoxy resin. It was originally···

15/11/2023

How to Design Parts for CNC MachiningDesigning parts forCNC machiningrequires a keen understanding o···

11/10/2023

Understanding CNC Machining PartsThe world of manufacturing has been revolutionized by the advent of···

24/08/2023

What will fiberglass sheets not stick to?

Fiberglass sheets are a versatile material used in various industries for their strength, durability, and resistance to moisture and chemicals. However, there are certain surfaces and materials that fiberglass sheets may not adhere to properly, which can affect the performance and longevity of the final product. In this article, we will explore the factors that influence the adhesion of fiberglass sheets and the surfaces that may pose challenges for bonding.

What are fiberglass sheets?

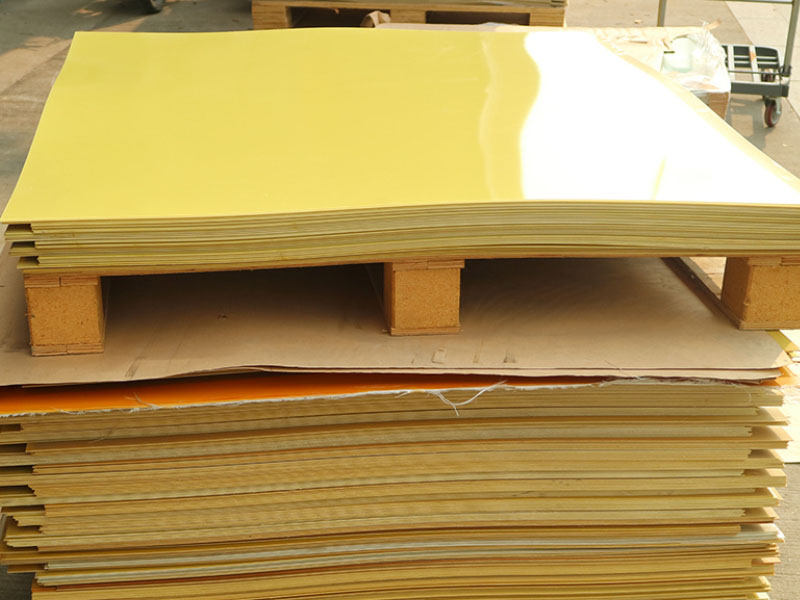

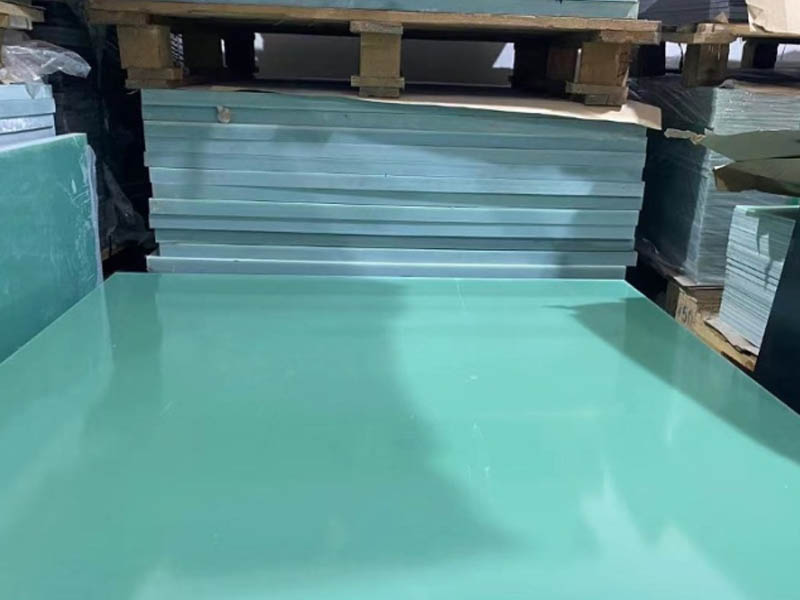

Fiberglass sheets are composite materials made from woven glass fibers embedded in a resin matrix, typically epoxy or polyester. These sheets are known for their high strength-to-weight ratio, resistance to corrosion, and ability to withstand extreme temperatures. They are commonly used in applications such as boat hulls, automotive parts, construction materials, and electrical insulation.

What factors influence the adhesion of fiberglass sheets?

Surface preparation

Proper surface preparation is crucial for achieving good adhesion of fiberglass sheets. The surface to which the fiberglass sheet is being bonded must be clean, dry, and free from contaminants such as oil, grease, dust, or moisture. Contaminants can create a barrier between the fiberglass and the substrate, preventing proper bonding.

Cleaning the surface with solvents such as acetone or isopropyl alcohol can help remove contaminants and promote better adhesion. Abrading the surface with sandpaper or a grinder can also improve adhesion by creating a rougher surface for the fiberglass to bond to.

Resin compatibility

The type of resin used in the fiberglass sheet can also affect adhesion. Different resins have different chemical compositions and properties, which can influence their ability to bond to various substrates. For example, epoxy resins generally provide better adhesion than polyester resins due to their superior chemical resistance and ability to cure in the presence of moisture.

It is important to choose a resin that is compatible with the substrate material and the intended application. Consulting the manufacturer’s specifications and recommendations can help ensure the right resin is selected for optimal adhesion.

Curing conditions

The curing conditions of the fiberglass sheet can also impact adhesion. Most resins require specific temperature and humidity conditions to cure properly and achieve maximum strength. If the fiberglass sheet is not cured under the recommended conditions, it may not bond properly to the substrate.

For example, if the fiberglass sheet is cured in a cold or damp environment, the resin may not fully harden, resulting in weak adhesion. Similarly, if the sheet is cured too quickly or at high temperatures, it may become brittle and lose its ability to bond effectively.

Environmental factors

Environmental factors such as temperature, humidity, and exposure to chemicals can also influence the adhesion of fiberglass sheets. High temperatures and humidity can accelerate the curing process, while low temperatures and humidity can slow it down. Additionally, exposure to harsh chemicals or solvents can weaken the bond between the fiberglass sheet and the substrate.

It is important to consider the environmental conditions during the application and curing process to ensure optimal adhesion. Taking precautions such as working in a controlled environment and using protective coatings can help mitigate the effects of environmental factors on adhesion.

Mechanical properties

The mechanical properties of the fiberglass sheet, such as its flexibility and tensile strength, can also affect adhesion. If the fiberglass sheet is too rigid or inflexible, it may not conform properly to the surface of the substrate, resulting in poor adhesion. Conversely, if the sheet is too flexible, it may not provide sufficient support or reinforcement, leading to weak adhesion.

Choosing the right thickness and type of fiberglass sheet for the specific application can help ensure optimal adhesion and performance. Consulting with a knowledgeable supplier or manufacturer can provide valuable guidance in selecting the appropriate fiberglass sheet.

What surfaces do fiberglass sheets not stick to?

Low-energy surfaces

Low-energy surfaces, such as certain types of plastics and rubber, can pose challenges for the adhesion of fiberglass sheets. These surfaces have low surface energy, which means they do not easily bond with other materials. As a result, fiberglass sheets may not adhere properly to low-energy surfaces, leading to delamination or separation over time.

To improve adhesion to low-energy surfaces, it may be necessary to use primers or adhesion promoters specifically designed for these types of substrates. These products can help increase the surface energy of the substrate and promote better bonding with the fiberglass sheet.

Non-porous surfaces

Non-porous surfaces, such as glass or polished metal, can also present challenges for the adhesion of fiberglass sheets. These surfaces are smooth and impermeable, making it difficult for the resin in the fiberglass sheet to penetrate and bond effectively.

To enhance adhesion to non-porous surfaces, it is important to properly prepare the surface by cleaning and abrading it. This can create a rougher texture for the resin to grip onto, improving the bond strength. Additionally, using a resin with good wetting properties can help ensure better adhesion to the non-porous surface.

Highly contaminated surfaces

Highly contaminated surfaces, such as those covered in oil, grease, or other contaminants, can significantly hinder the adhesion of fiberglass sheets. Contaminants can create a barrier between the fiberglass and the substrate, preventing proper bonding.

Thoroughly cleaning the contaminated surface is essential for achieving good adhesion. This may involve using strong solvents or degreasers to remove stubborn contaminants. It is important to follow the manufacturer’s instructions and take appropriate safety precautions when working with these chemicals.

Wet surfaces

Applying fiberglass sheets to wet surfaces can lead to poor adhesion and compromised performance. Moisture can interfere with the curing process of the resin, preventing it from hardening properly and forming a strong bond.

To ensure optimal adhesion, it is crucial to apply fiberglass sheets to dry surfaces. This may require waiting for the surface to dry completely or using heat lamps or fans to accelerate the drying process. Additionally, using moisture-resistant resins can help mitigate the effects of moisture on adhesion.

High-temperature surfaces

Applying fiberglass sheets to high-temperature surfaces can also pose challenges for adhesion. Excessive heat can cause the resin to cure too quickly, preventing it from properly bonding to the substrate. It can also lead to thermal expansion and contraction, which may cause the bond to weaken over time.

To improve adhesion to high-temperature surfaces, it is important to use resins specifically formulated for high-temperature applications. These resins are designed to withstand elevated temperatures and maintain their adhesive properties. Additionally, controlling the application temperature and ensuring proper curing conditions can help enhance adhesion.

Conclusion

In conclusion, fiberglass sheets can be a durable and versatile material for various applications, but their adhesion can be influenced by several factors. Proper surface preparation, resin compatibility, curing conditions, and environmental factors all play a crucial role in determining the bond strength of fiberglass sheets.

To achieve optimal adhesion, it is important to carefully consider the surface to which the fiberglass sheet will be bonded and take the necessary steps to prepare it. By addressing these factors, the challenges associated with bonding fiberglass sheets can be minimized, ensuring the longevity and performance of the final product.