Recent Posts

Epoxy gasketis a kind of high temperature resistant anti-corrosion sealing gasket, which can directl···

22/01/2025

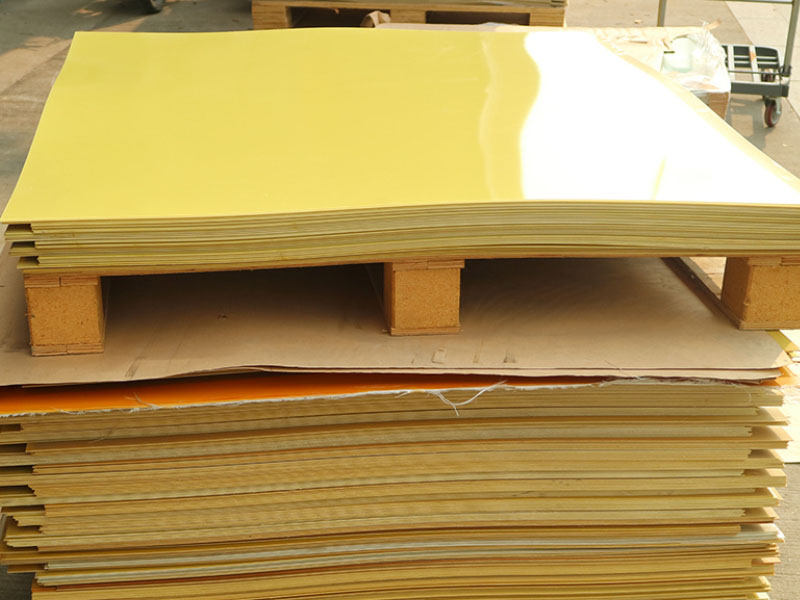

Epoxy boardis a commonly used material now, and the raw materials for production include epoxy resin···

01/12/2024

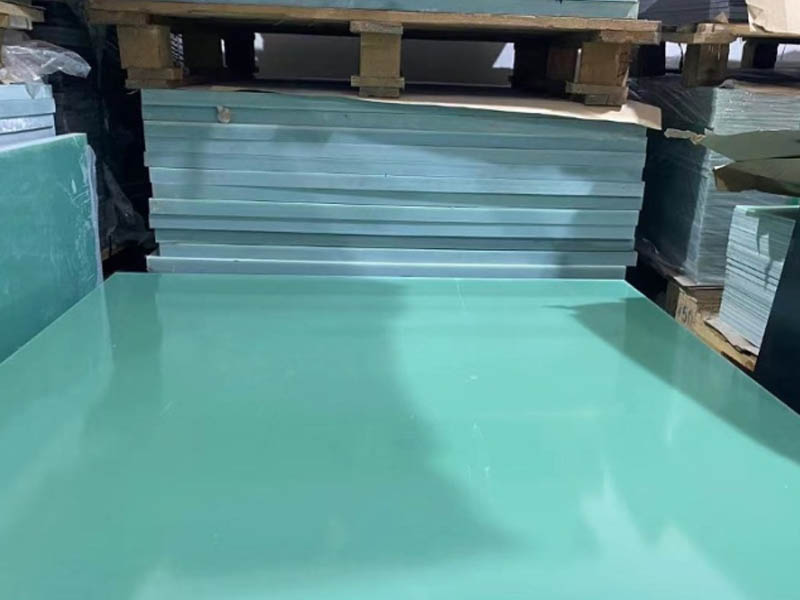

Epoxy boardis a commonly used electronic and electrical material, which has the characteristics of h···

20/06/2024

G10 Materialis a composite material composed of glass fiber cloth and epoxy resin. It was originally···

15/11/2023

How to Design Parts for CNC MachiningDesigning parts forCNC machiningrequires a keen understanding o···

11/10/2023

Understanding CNC Machining PartsThe world of manufacturing has been revolutionized by the advent of···

24/08/2023

How to design parts for CNC machining?

How to Design Parts for CNC Machining

Designing parts for CNC machining requires a keen understanding of both the capabilities and limitations of the CNC machining process. By following specific design principles, engineers and designers can create parts that are not only functional but also cost-effective to manufacture. This guide will delve into the essential aspects of designing for CNC machining, ensuring your CNC machining part meets the desired specifications and performance criteria.

Understanding CNC Machining Capabilities

The first step in designing a CNC machining part is to understand the capabilities of CNC machining. This manufacturing process excels at creating precise parts with tight tolerances. However, it's important to recognize the impact of tool access on your design. Complex shapes may require specialized tooling or even multi-axis CNC machines, which can significantly impact the cost and time required for production.

Incorporating features like radii in internal corners can greatly improve manufacturability. Instead of sharp corners, which are challenging to machine, rounded corners allow the cutting tool to move smoothly, reducing wear and tear on the tool and ensuring a higher quality surface finish.

Optimizing Design for Cost-Effectiveness

Cost-effectiveness is a crucial consideration when designing parts for CNC machining. Simplifying your design can lead to significant savings in both time and materials. For instance, minimizing the number of tool changes required by using common hole sizes can speed up the manufacturing process.

Additionally, considering material selection from the outset is essential. Different materials behave differently during the CNC machining process, with some being easier to machine than others. Selecting a material that is well-suited to your part's functional requirements