Recent Posts

Epoxy gasketis a kind of high temperature resistant anti-corrosion sealing gasket, which can directl···

22/01/2025

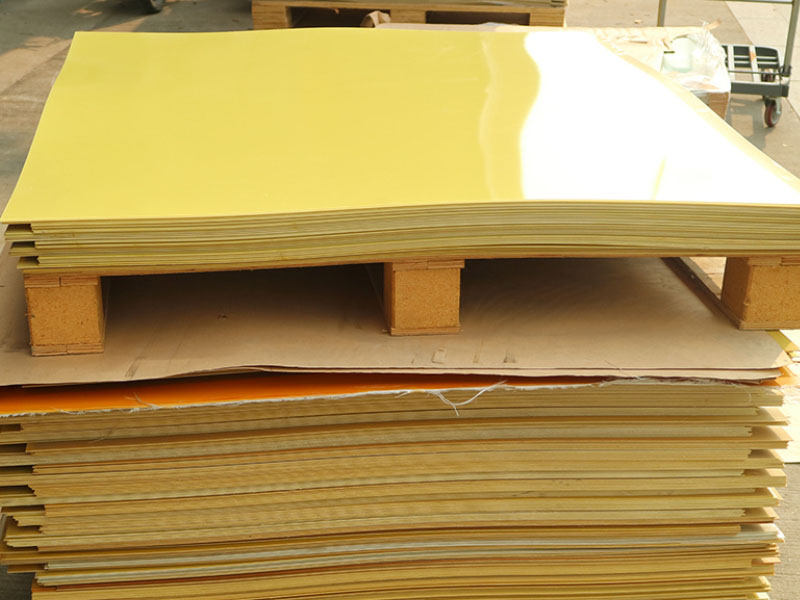

Epoxy boardis a commonly used material now, and the raw materials for production include epoxy resin···

01/12/2024

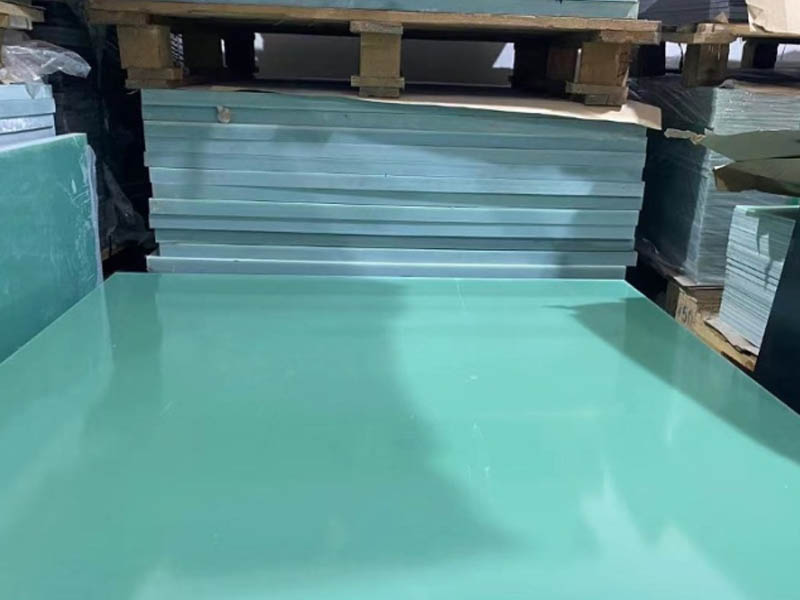

Epoxy boardis a commonly used electronic and electrical material, which has the characteristics of h···

20/06/2024

G10 Materialis a composite material composed of glass fiber cloth and epoxy resin. It was originally···

15/11/2023

How to Design Parts for CNC MachiningDesigning parts forCNC machiningrequires a keen understanding o···

11/10/2023

Understanding CNC Machining PartsThe world of manufacturing has been revolutionized by the advent of···

24/08/2023

What does CNC machining part include?

Understanding CNC Machining Parts

The world of manufacturing has been revolutionized by the advent of CNC (Computer Numerical Control) technology, making the production of complex and precise parts faster and more efficient. A CNC machining part encompasses a wide array of components produced using CNC machines, which are indispensable in various industries including automotive, aerospace, and electronics. This comprehensive exploration delves into what constitutes a CNC machining part, the materials commonly used, the processes involved in their creation, and their applications across different sectors.

Components of a CNC Machining Part

CNC machining parts are characterized by their intricate designs and precise dimensions, achievable through the sophisticated control of CNC machines. These parts can range from simple bolts and screws to more complex components such as engine parts or airplane fuselage sections. The versatility of CNC machining lies in its ability to produce both standard and custom parts, catering to a broad spectrum of industrial needs.

Materials Used in CNC Machining

The choice of material for a CNC machining part is crucial, influencing both the manufacturing process and the part's performance in its final application. Common materials include metals such as aluminum, steel, and titanium, known for their strength and durability. Plastics like ABS and polycarbonate are also frequently used for parts requiring good mechanical properties and resistance to impact.

The CNC Machining Process

Creating a CNC machining part involves several steps, starting with design and ending with the finished product. Initially, engineers use CAD (Computer-Aided Design) software to model the part. CAM (Computer-Aided Manufacturing) software then converts these models into machine-readable instructions. The CNC machine precisely cuts, drills, or shapes the material based on these instructions, producing parts with tolerances as tight as a few micrometers.

Applications of CNC Machining Parts

The applications of CNC machining parts are vast and varied. In the automotive industry, they are used in the manufacturing of engine components, transmission parts, and custom fittings. Aerospace applications include structural components, landing gear parts, and intricate fuel system components. Electronics manufacturers rely on CNC machining for the creation of enclosures, heat sinks, and connectors.

Innovations in CNC Machining

As technology advances, so too does the capability of CNC machining. Innovations such as 5-axis machining centers allow for the production of parts with complex geometries that were previously impossible or too costly to manufacture. This has opened up new possibilities for design and engineering across all industries that utilize CNC machining parts.

Sustainability in CNC Machining

Environmental considerations are increasingly becoming a priority in manufacturing. Efforts to make CNC machining more sustainable include optimizing cutting strategies to reduce waste, using recycled materials for part production, and improving machine energy efficiency. These steps not only reduce the environmental impact but can also lead to cost savings for manufacturers.

Conclusion

In summary, a CNC machining part represents a cornerstone in modern manufacturing, offering unparalleled precision and flexibility. From the materials chosen to the final applications, these parts play a critical role in driving innovation and efficiency across multiple industries. As CNC technology continues to evolve, we can expect to see even greater advancements in the quality, complexity, and sustainability of manufactured parts.