Recent Posts

Epoxy gasketis a kind of high temperature resistant anti-corrosion sealing gasket, which can directl···

22/01/2025

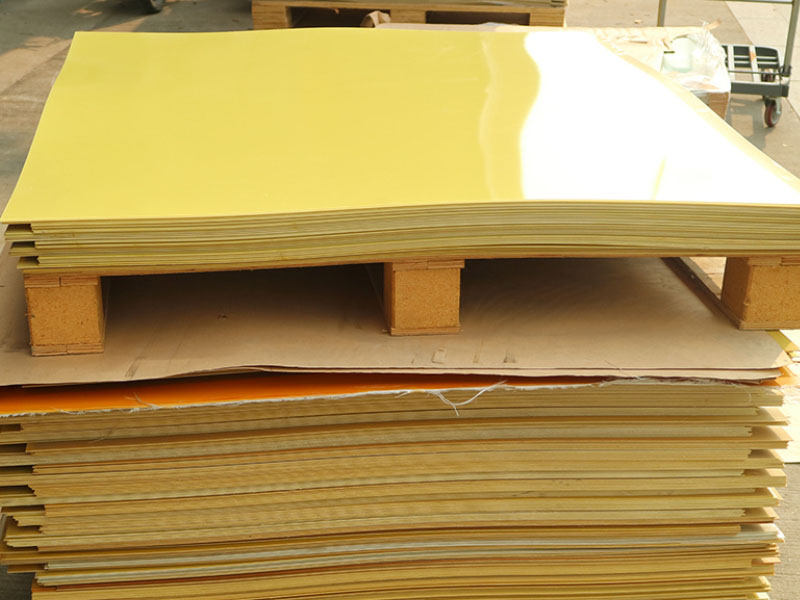

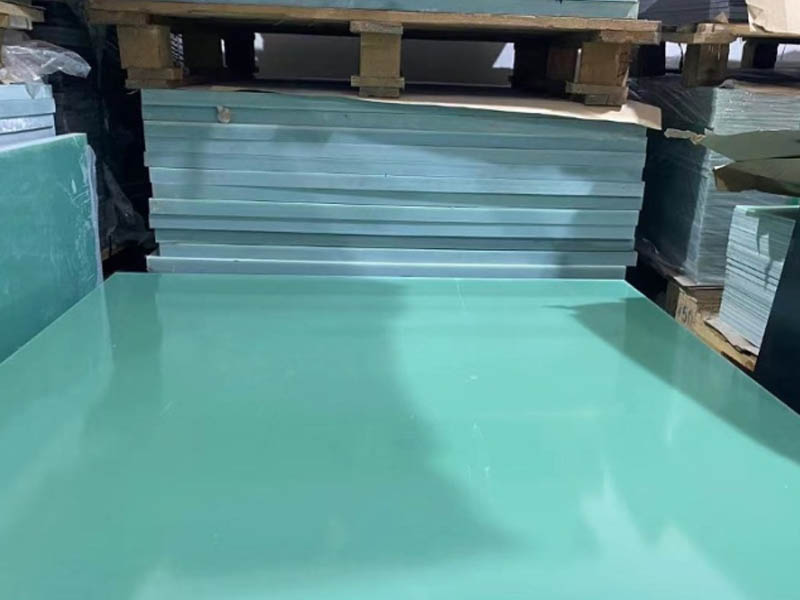

Epoxy boardis a commonly used material now, and the raw materials for production include epoxy resin···

01/12/2024

Epoxy boardis a commonly used electronic and electrical material, which has the characteristics of h···

20/06/2024

G10 Materialis a composite material composed of glass fiber cloth and epoxy resin. It was originally···

15/11/2023

How to Design Parts for CNC MachiningDesigning parts forCNC machiningrequires a keen understanding o···

11/10/2023

Understanding CNC Machining PartsThe world of manufacturing has been revolutionized by the advent of···

24/08/2023

What points should be paid attention to on selecting epoxy gaskets?

Epoxy gasket is a kind of high temperature resistant anti-corrosion sealing gasket, which can directly contact with flame, and mainly works in high temperature and anti-corrosion environment. The cost is low, and it is an ideal high temperature resistant and anticorrosive gasket. Many products used in life are processed by epoxy board material FR4/G10/3240, etc., because epoxy board material has good insulation properties and can be used in various products. Performance characteristics such as good heat insulation and certain toughness.

What points should be paid attention to when selecting?

1. The surface of the gasket body is not allowed to have scars, voids, unevenness and rust spots that affect the sealing performance. The non-metallic band on the surface of the gasket body should be even and appropriately higher than the metal band, and the interlayer texture should be clear, but the metal band should not be exposed. The solder joint spacing of metal spiral wound gaskets should be uniform, and there should be no defects such as lack of fusion or over-melting.

2. The surface should not have defects such as burrs, unevenness, rust spots, etc. The distance between the upper and lower sealing surfaces of the gasket body and the upper and lower surfaces of the reinforcement ring should be equal. The inner reinforcement ring and the gasket body should be tightly fixed and not loose; The main body of the gasket should be positioned and loosened appropriately.

3. Compression rate, resilience rate and sealing performance are important performance indicators of epoxy gaskets. Generally speaking, under the premise of meeting the compression rate requirements, the higher the resilience rate, the better; while meeting the requirements of the resilience rate standard Under the premise of, the test value of the compression ratio is better. Products with good sealing performance, moderate compression rate and the largest possible rebound rate should be selected.