Recent Posts

Epoxy gasketis a kind of high temperature resistant anti-corrosion sealing gasket, which can directl···

22/01/2025

Epoxy boardis a commonly used material now, and the raw materials for production include epoxy resin···

01/12/2024

Epoxy boardis a commonly used electronic and electrical material, which has the characteristics of h···

20/06/2024

G10 Materialis a composite material composed of glass fiber cloth and epoxy resin. It was originally···

15/11/2023

How to Design Parts for CNC MachiningDesigning parts forCNC machiningrequires a keen understanding o···

11/10/2023

Understanding CNC Machining PartsThe world of manufacturing has been revolutionized by the advent of···

24/08/2023

How to judge whether the epoxy insulating board reaches the specified temperature?

Epoxy board is a commonly used electronic and electrical material, which has the characteristics of high temperature resistance, corrosion resistance, friction resistance, light weight and insulation. The high temperature resistance of different types of epoxy boards is different. The most commonly used temperature is about 130℃-150℃, and the high temperature resistance can reach more than 200℃. So, how to judge whether the epoxy board has reached the specified temperature?

1. Heat the epoxy board

Deformation occurs when heated to a certain temperature: mainly including bending, shrinking, expansion, and warping of the insulating board. Once the temperature exceeds the range, the internal stress changes, and the shape of the epoxy board changes, and it cannot be restored to its original appearance.

2. Delamination on heating

We know that epoxy board is a composite material. It is a laminated structure, a layer of glass fiber cloth and a layer of resin. If the temperature is too high, the bonding force of the resin will be destroyed, leading to delamination. Therefore, when the epoxy board is heated to the specified temperature, if the epoxy board is delamination, it means that the epoxy board has not reached the specified temperature and does not meet the requirements.

3. Cracking on heating

Perform a heating test on the epoxy board. If you see a gap on the surface of the epoxy board during the heating to the specified temperature, and the thickness gradually deepens, it will crack directly if the temperature is not lowered in time. This phenomenon can also fully explain that the epoxy board has not reached the specified temperature and is a substandard product.

4. Blushing on heating

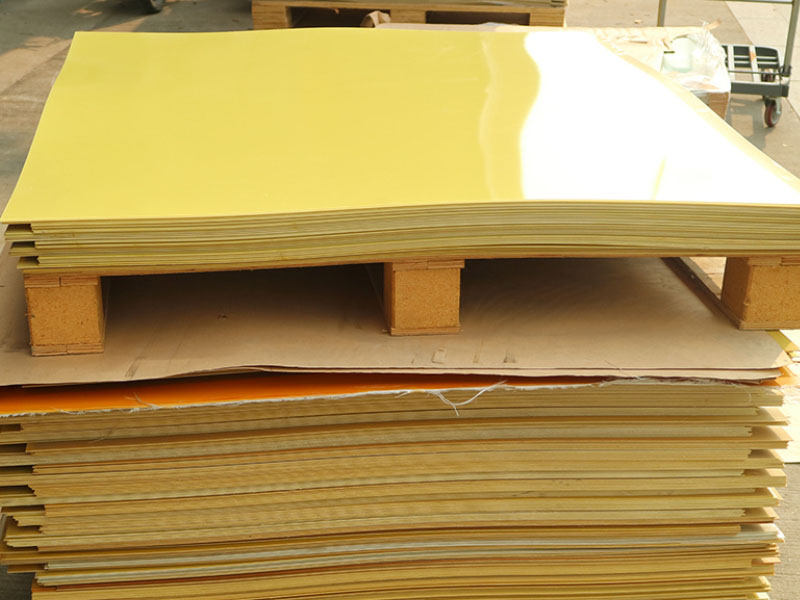

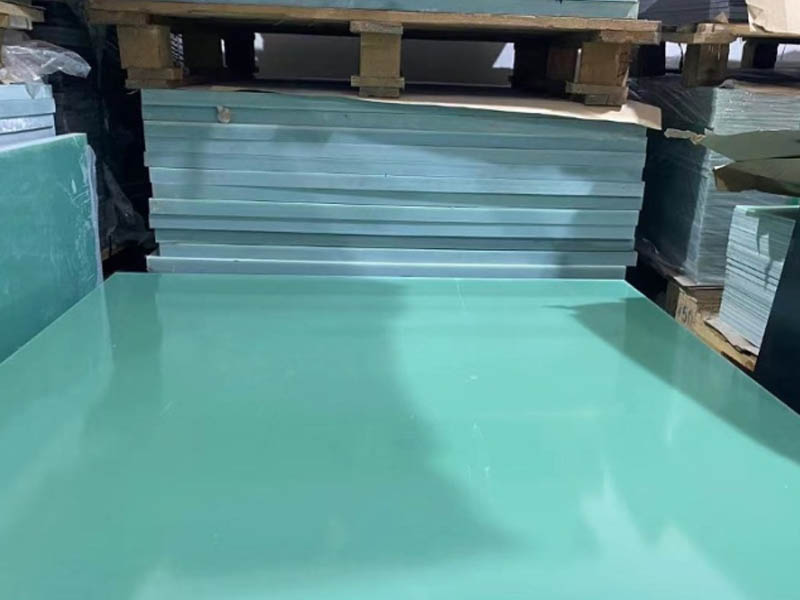

As we all know, the colors of epoxy boards are mostly yellow, aqua and black. It can be said that the color change directly reflects the defense of the internal performance of the epoxy board. If during the heating test of the epoxy board, it has not reached the specified temperature, it is a bad phenomenon that the epoxy board gradually turns white. It can be said that there is a problem with the quality of the product.