Recent Posts

Epoxy gasketis a kind of high temperature resistant anti-corrosion sealing gasket, which can directl···

22/01/2025

Epoxy boardis a commonly used material now, and the raw materials for production include epoxy resin···

01/12/2024

Epoxy boardis a commonly used electronic and electrical material, which has the characteristics of h···

20/06/2024

G10 Materialis a composite material composed of glass fiber cloth and epoxy resin. It was originally···

15/11/2023

How to Design Parts for CNC MachiningDesigning parts forCNC machiningrequires a keen understanding o···

11/10/2023

Understanding CNC Machining PartsThe world of manufacturing has been revolutionized by the advent of···

24/08/2023

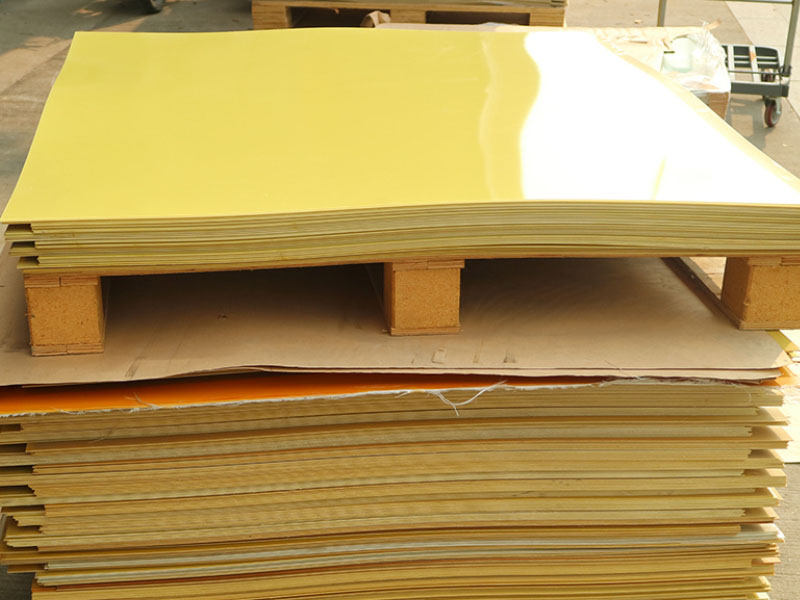

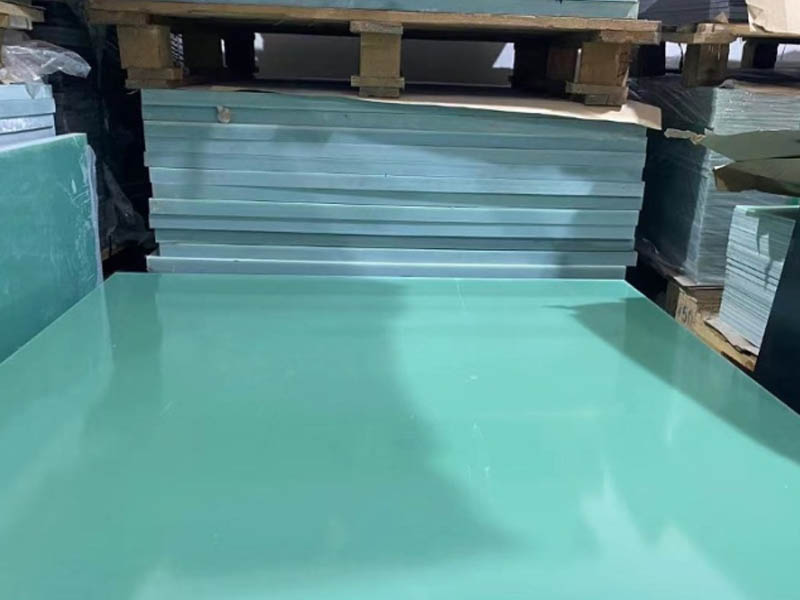

What is the use of epoxy fiberglass sheet?

Epoxy fiberglass sheet, a composite material known for its robustness and versatility, has become a staple in various industries. Its unique properties, stemming from the combination of epoxy resin and fiberglass, offer a wide array of applications, making it an essential material in modern manufacturing and design projects.

The Basics of Epoxy Fiberglass Sheet

At its core, an epoxy fiberglass sheet is made by reinforcing epoxy resin with fiberglass. This process creates a material that is not only strong but also resistant to many forms of degradation, including corrosion, moisture, and thermal stress. This durability makes the epoxy fiberglass sheet a preferred choice for many engineers and designers.

Composition and Manufacturing

The manufacturing process of epoxy fiberglass sheets involves impregnating fiberglass with epoxy resin and then curing it under heat and pressure. This method ensures that the sheets have a uniform structure and thickness, providing consistent quality across applications.

Key Properties

Epoxy fiberglass sheets boast impressive strength-to-weight ratios, electrical insulation properties, and resistance to chemical and environmental factors. These characteristics are crucial for their performance in demanding conditions.

Applications in Various Industries

The versatility of epoxy fiberglass sheets allows them to be used in a myriad of applications across different sectors. From aerospace to electronics, these sheets provide solutions that enhance the durability, safety, and functionality of products and structures.

Aerospace and Automotive

In the aerospace and automotive industries, the lightweight yet strong nature of epoxy fiberglass sheets contributes to fuel efficiency and structural integrity. Components like body panels, seats, and engine covers are commonly made from this material.

Electrical and Electronics

Given their excellent electrical insulation properties, epoxy fiberglass sheets are extensively used in the electrical and electronics sector. They serve as insulators in circuit boards, transformers, and other electrical components, preventing short circuits and ensuring user safety.

Building and Construction

The construction industry benefits from the use of epoxy fiberglass sheets in roofing, cladding panels, and structural reinforcements. Their durability and resistance to environmental factors make them ideal for both interior and exterior applications.

Advantages Over Other Materials

Epoxy fiberglass sheets offer several advantages over traditional materials like metal, wood, or plastic. Their superior strength, combined with resistance to corrosion, wear, and environmental impacts, provides a longer lifespan and lower maintenance costs.

Cost-Effectiveness

Despite their high performance, epoxy fiberglass sheets are cost-effective solutions for many projects. Their durability means less frequent replacements, translating into savings over time.

Design Flexibility

The malleability of epoxy fiberglass sheets before curing allows for the creation of complex shapes and forms. This flexibility opens up new design possibilities, enabling innovative applications that were previously unattainable with more rigid materials.

Environmental Considerations

As industries move towards more sustainable practices, the environmental impact of materials becomes increasingly important. Epoxy fiberglass sheets contribute to this shift by being durable and requiring less frequent replacement. However, it's essential to consider the entire lifecycle of the product, including manufacturing and disposal processes, to fully understand its environmental footprint.

Efforts are being made to improve the recyclability of epoxy fiberglass sheets. Research into new methods for breaking down the composite materials without compromising their integrity is ongoing, aiming to enhance their sustainability further.

In conclusion, the use of epoxy fiberglass sheet spans across various industries due to its unmatched properties such as strength, durability, and resistance to a wide range of damaging factors. Its role in advancing technological and design innovations continues to grow, making it a critical material in shaping the future of manufacturing and construction.